We sat down with Managing Director, Neil Fletcher to ask him some questions about this stunningly successful international company.

What is Invert Robotics?

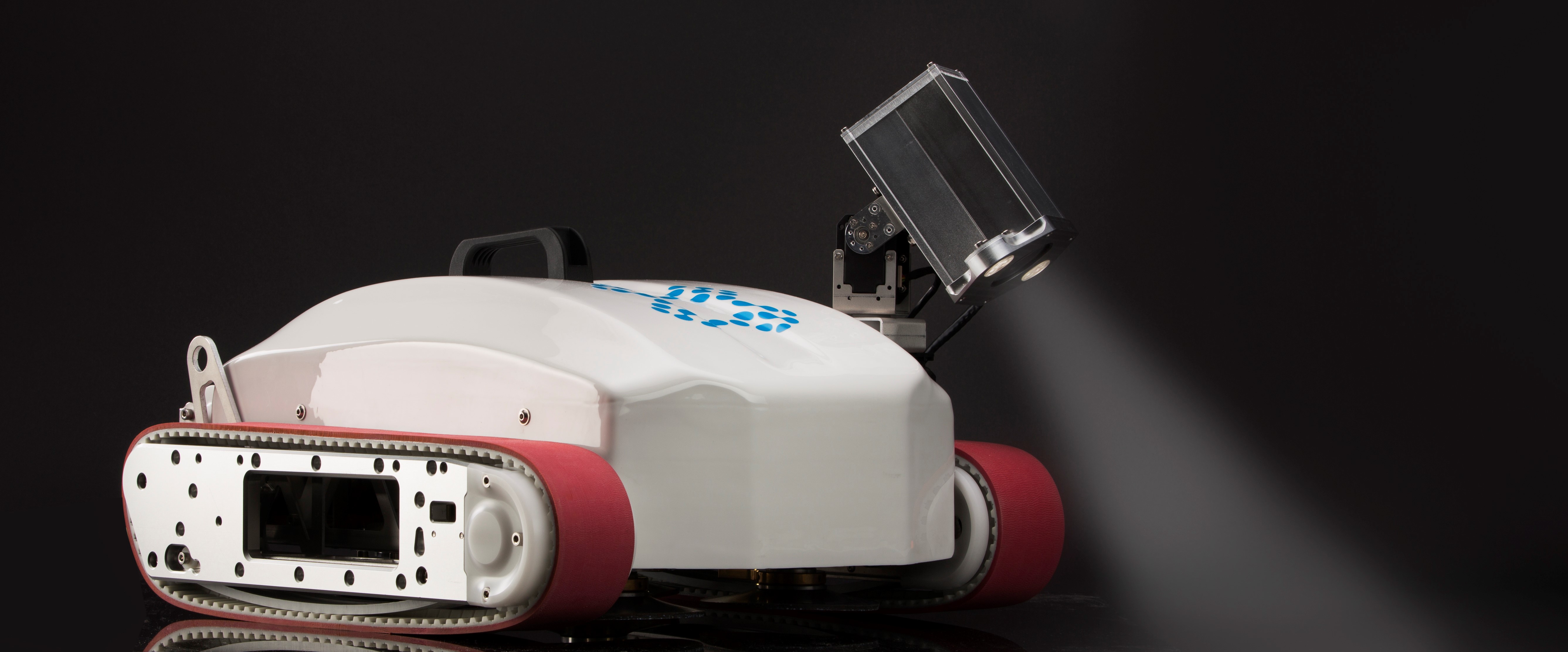

“Invert Robotics is a company that has designed, developed and manufactured a unique robot that can climb on non-magnetic surfaces, such as carbon-fibre, stainless steel, and aluminium. There are no other commercial robots in the world that can do this.

The robot can climb various assets like aircraft and dairy powder dryers and is used to test the structure for integrity or damage. We attach speciality probes onto the robot which enable us to identify cracks and defects and measure their size and depth.

The company has two main divisions; the technology arm is based here in Christchurch and develops and manufactures the robotic solutions. The service delivery arm provides inspection services to companies with high-value assets, like dairy companies and breweries. Our employees take the mobile robots to customers sites, perform the inspection and deliver an assessment report on the asset. We currently have sales and services offices in NZ, the Netherlands and Germany.

Where does the technology come from?

“Mobile robotics is a key research area at the University of Canterbury and in 2010, Professor Professor XiaoQi Chen of the Engineering School developed a novel mobile robot that utilised the Bernoulli Effect to attach and detach from vertical surfaces.

Powerhouse got involved in the early days with that project and funded James Robertson to develop the technology into a product and find a commercial application.”

"Powerhouse got involved in the early days.."

Invert's world-famous robot "Alfie"

How was the concept developed?

We don’t rely on the original patent developed by Professor XiaoQi Che as ultimately it was not suitable for commercial use. James took the original research and after discussions with potential end-users including Fonterra, re-developed the mobile robot to use a passive sliding suction cup system. This was a significant advancement. By removing the need for pressurised air to run the system, it reduced energy requirements and improved payload capabilities thereby enabling broad commercial application.

James then took the new prototype to market and undertook the necessary testing to prove efficacy. By 2013, James and his team had launched commercial services and were providing industrial inspection to the major dairy companies in NZ.

How did you raise capital?

"Initially we had a small group of local private investors who were very supportive of the company through the high-risk product development and market entry phases. The people who invested early, were people who really believed in the team and the technology. Now of course, with more than $10M invested to date, we have a much larger pool of local and international private shareholders but we are lucky that they all share the same vision for the company”

How is your international expansion developing?

“Our latest capital round was primarily focused on accelerating our global expansion. The food and dairy services business is going from strength to strength and we have just opened our second European office in Bremen Germany and we are looking to open offices in Denmark and France in the near future. We are working hard to get sales people on the ground in Europe so we can hit our ambitious revenue targets.

Other industries like fine chemicals, petrol chemicals and aviation are also going really well. These industries are new for us but we are cementing relationships with key clients in each sector and working to develop inspection solutions specific to the client needs. These industries are more likely to develop into a lease business model than a services model, but our first challenge is to tailor our technology for each market and find the best staff to accelerate these opportunities.”

Is there any competition - and if so, how do you intend to disrupt the market?

“Of course, there is always competition. There are no other robotic solutions in the food, dairy and beverage market but there is a lot of research into the robtoics area globally. The market incumbent is rope access inspection which is basically people hanging from ropes using torches or probes to find cracks. Dye penetrant testing is also very popular and this involves applying penetrant and fluorescing it to identify cracks. Both solutions are manual human methods which are time-consuming and pose health and safety risks.

A relative market new-comer is drone based inspections; however they’re unstable, have a very short battery life, and are not manoeuvrable in confined spaces, so their application is limited.

What are the 3-4 industry verticals you’re building out?

“Originally, our business was targeted at dairy, then that became food and dairy. Dairy grew into food processing, which grew into beer and powdered drinks. We now call it all one vertical - food, dairy and beverage. Not a lot of companies that do all three.

Next came aviation, which is still very early. In the aviation business instead of direct services, we lease the robots to the airline maintenance companies. Our first major contract is now underway.

Then there’s petrochemical/fine chemicals which will likely be a blend of lease and direct service, depending on customer need. There are a number of other verticals that we know we can work in but we don’t have the capacity to deal with them just yet. Watch this space."

How has Powerhouse been involved in Invert’s success to date?

“In the early days, Powerhouse provided initial funding, provided valuable IP advice, found and appointed James and provided introductions for James to some of the early investors, who together got the company up and running.

Now we have largely outgrown Powerhouse’s direct services, but it is good have their continued support as we move through our growth phases.

Thank you for your time Neil and good luck to you and Alfie!

For more information on Invert Robotics, head to their website:

www.invertrobotics.com